Unlocking secreta Engineering Machinery Efflections: Material Electio et ejus impulsum in perficientur

2025.04.01

2025.04.01

News industria

News industria

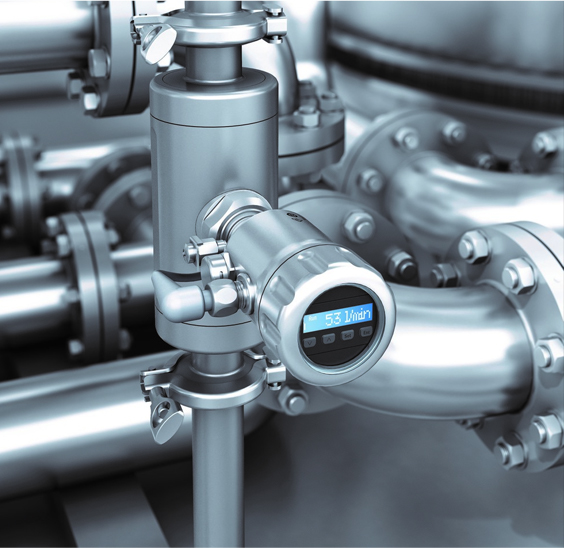

Machinery engineering Sunt essentialia components in variis industriae applications, a gravibus, officium machinery ad complexu apparatu quod petit utrumque praecisione et diuturnitatem. Success horum delectationum incipit cum crucial gradum: Material Electio. In this article, we’ll dive into the process of choosing the right materials for engineering machinery forgings, exploring how different alloys and steels affect the final product’s performance, and why getting it right is key to ensuring that these components can handle the extreme conditions they’re designed for.

Intelligentes Material Electio enim Engineering Machinery Dontibus

Material Electio est prima et maxime discrimine consilium in fabrica processus. Mechanica proprietatibus de materia, ut sua fortitudo, lenta, gerunt resistentia, et facultatem ad sustinere altum temperaturis, recta afficit ad perficientur de engineing machinery remittit. Sive suus ipsum Steel, Alloy ferro, vel immaculatam ferro, quisque materiam brings unicum commoda ad mensam.

Carbon Steel: De omnibus, Rounder ad Engineering Machinery Rotular

Carbon Steel est popularis choice pro multis colaging applications debitum ad optimum statera roboris et ductility. Suus 'sumptus-effective et offert bonum perficientur modice temperatus environments. Hoc facit carbonis ferro ad materiam ad engineering machinery remissos, qui requirere reliability sine necessitate pro speciali resistentia ad extremam conditionibus. Versatum concedit lata rhoncus usuum ex structural partes ad partes subiecto mediocribus gerunt et lacrimam.

Alloy Steel: Tailoring Deltings ad gravibus-officium Applications

Nam magis postulat applications, alleo steels saepe malle arbitrium. Per addendo elementa sicut chromium, Molybdenum, aut Vanadium, ally ferro potest esse machinatum ad exhibent specifica proprietatibus ut auctus duritia, magis resistentia ad calorem, et meliorem gerunt resistentia. Haec tailored proprietatibus facere mixed steels specimen pro engineering machinatione remittit, quod agunt in dura environments, sicut anni, sagittis, et engine components, quod est permanere assidue frictio, princeps pressura, et temperatus extremi.

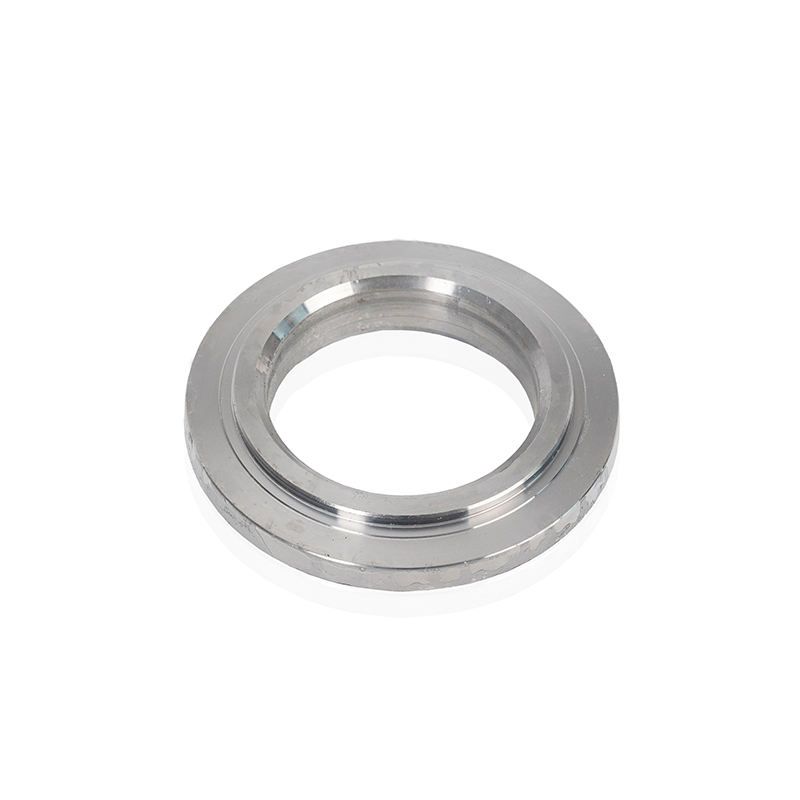

Aliquam ferro, in ultima in corrosio resistentia

In industrias ubi corrosio resistentia est non-MERCABILIS, immaculatam ferro stat ex ut materia electionis pro ipsum machinery remittings. Praeterea chromium facit immaculatam ferro repugnans oxidatio et rubigo, faciens idoneam machinarios patere umor, oeconomiae et extrema environmental conditionibus. Machinery engineering Communiter in cibum processus, eget processus, et Marinus Applications, ubi longa-term diuturnitatem et resistentia ad corrosit elementa sunt.

In partes calor curatio in enhancing fusi perficientur

Semel in materia est electus, altera discrimine gradus in producendo summus qualitas ipsum machinery remittings est calor curatio. Calor curatio potest dramatically amplio mechanica proprietatibus materiae, inter suae duritia, vires, et lentitia. Nam exempli gratia, extinguendas et temperatio processibus potest augendae gerunt resistentia et lassitudine robore Alloy Steels, faciens eos magis idoneam ad altus-accentus applications.

In temperatus ad quod materia est calor-tractata ludit a significant munus in determinandum ad ultima grano structura, quae rursus afficit materiale est scriptor perficientur. A fine, uniformis frumentum structuram effectum per imperium calor curatio ensures ut rem deludes sunt magis resistentia ad crepuit et potest resistere iteratis loading CYCLUS, quod est essential et components sicut Turbine Lamina et Engine Parts.